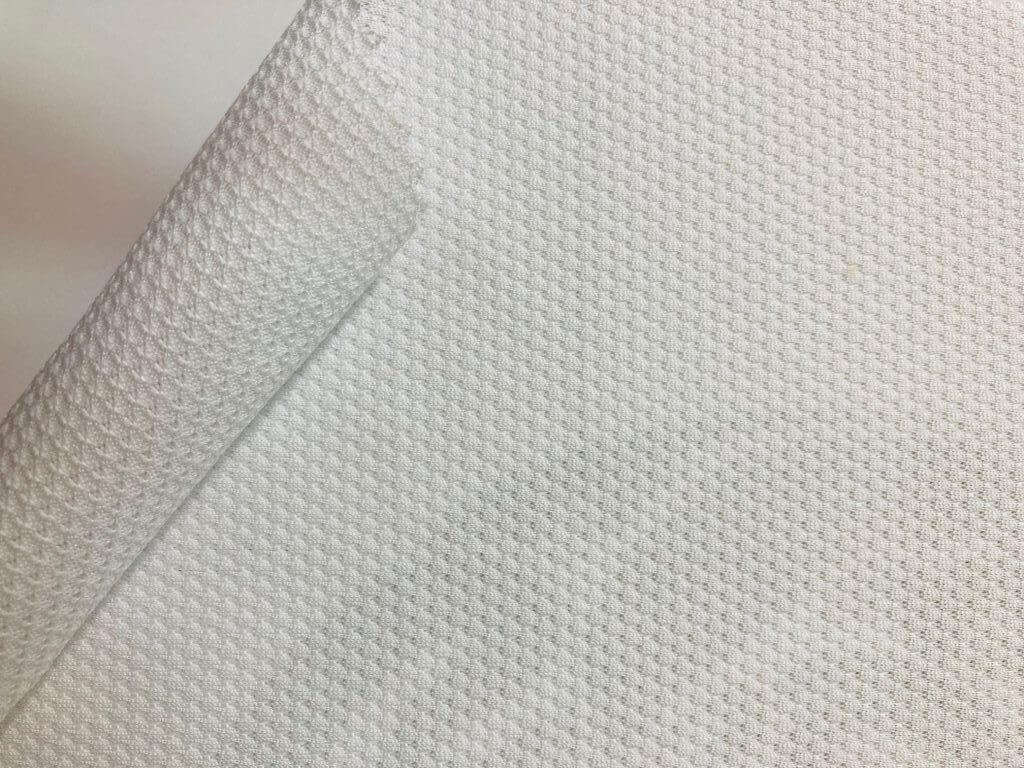

Antimicrobial fabric

20/05/2021 2023-10-30 16:19Antimicrobial fabric

Antimicrobial fabric is a textile that offers protection against bacteria, mold, mildew, and other hazardous microbes. This can be achieved by treating the fabric with a proprietary topical chemical that inhibits the growth of pathogens or by using yarns which are designed to provide inherent microscopic antimicrobial functionality such as those found in high performance fabric constructed with specialty yarns. In combination, these yarns fight microbes from developing while simultaneously promoting moisture movement, thereby maximising comfort and extending the life of the fabric. Antimicrobial fabric must be non-toxic to the consumer and the environment and demonstrate compliance with regional health authorities through approved third-party testing. For this reason, it’s essential for a knowledgeable supplier to be aware of the customer’s requirements.

How does antimicrobial fabric work ?

Antimicrobial fabric works the same way antimicrobial soaps and sanitisers do, that is, by attacking pathogens on a cellular level to prevent their growth and reproduction. Different chemicals and textiles have different levels of effectiveness. Some products merely slow the spread of pathogens over time, while others are designed to kill spore cells on contact. Clothing and linens offer a porous, warm and hard-to-clean environment that is ideal for microbe growth. One of the reasons antimicrobial material fabrics are so effective is that, by eliminating this hazard, they keep dangerous pathogens from spreading, which reduces the overall risk of infection in a hospital or other area where sanitation is essential.

Where are antimicrobial fabrics used ?

Clothes and hospital scrubs, as well as medical mattress covers, fabric and upholstery often use specially treated textiles to reduce the risk of disease transmission and prevent infection. Antimicrobial fabric is manufactured for healthcare, orthopaedic and other companies. Another important antimicrobial fabric application is military and defence contracting, where it is a component of counter-chemical/biological warfare garments and related equipment. Antimicrobial fabric also makes an excellent choice for footwear and athleticwear, where they help prevent odours. They can also find themselves applicable across industries — from automotive and contract furniture fabric to food packaging, safety gear and more.

Antimicrobial fabric is now witnessing a heightened demand and relevance now more than ever as the pandemic continues to impact people’s health and their livelihood. With the increased demand for hygiene and sanitisation, as well as healthcare gear, manufacturers are inventing ways of creating new forms of antimicrobial fabric. Such innovative developments are supported at JD Institute’s textile design course that enables students to create textile design that is functional and purposeful to the current context of the world.