Innovation in Sustainable Dyeing by way of Waterless Process

16/08/2021 2021-08-16 14:45Innovation in Sustainable Dyeing by way of Waterless Process

“Innovation in Sustainable Dyeing” hosted on 28th July 2021 was part of CONV. (Conversation) – 3C’s Outreach Program. The session was presided by Dr. Swapneshu Baser, Founder Director of Deven Supercriticals Pvt. Ltd. He has played a vital role in the design, development and implementation of ‘Supercritical Fluid Processing Technology’.

Dr. Baser was associated with SCF Technology development activity at IIT-Bombay since its commencement in 1993. He shared key responsibility for SCF technology development and then continued with it in DSPL. His organisation holds number of national and international patents for Process for Dyeing of Textile Materials using Supercritical Fluid; System for Continuous Feeding and Discharging of Solid Material to and from a Vessel Operating under High Pressure and A Control Valve having Hollow Piston for Controlling Flow of Fluid.

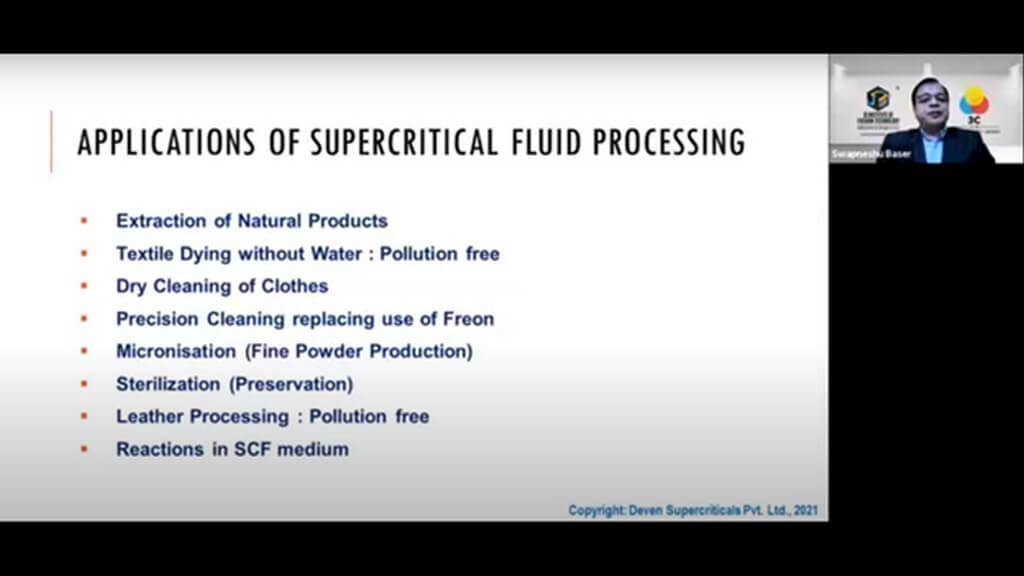

Supercritical Fluid can be used for number of natural products for instance extraction of spice oils, fragrances, essential oils etc. The residue from the use of SCF is next to nothing and there is not degradation of the product.

The freon can be replaced for cleaning or other solvent for cleaning either of clothes or industrial components. Supercritical Fluids is used for that kind of application. Micronisation of pharmaceutical components can be carried out as well. For example, treatment of asthma patients uses a pump. This contains fine powder, so this powder can be made by using Supercritical Fluids. Products can be sterilized too. Some of the most polluting processes of Leather processing can be replaced and some reactions also advantageously be balanced with Supercritical Fluids.

The freon can be replaced for cleaning or other solvent for cleaning either of clothes or industrial components. Supercritical Fluids is used for that kind of application. Micronisation of pharmaceutical components can be carried out as well. For example, treatment of asthma patients uses a pump. This contains fine powder, so this powder can be made by using Supercritical Fluids. Products can be sterilized too. Some of the most polluting processes of Leather processing can be replaced and some reactions also advantageously be balanced with Supercritical Fluids.

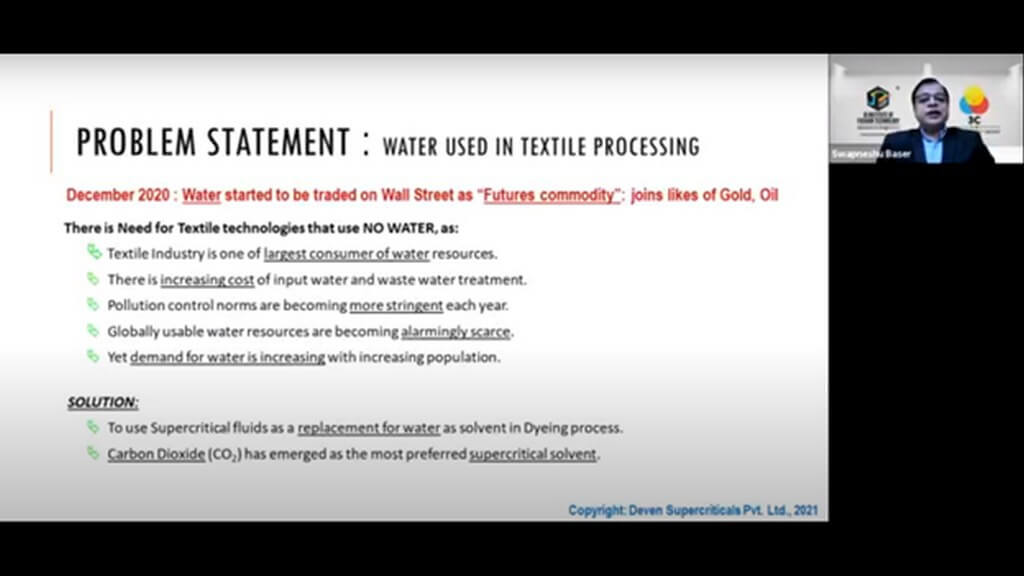

There is a scarcity of water. The textile industry is one of the largest consumers of water. Dr. Baser shared that in December 2020, water started to be treaded on Wall Street as “Futures Commodity” just like Gold and Oil. This is alarming as we are aware that markets normally predict the future and this trend evidently points towards the fact that water will be scarce in the coming years. In traditional textile dyeing, large amounts of water are used both in terms of intake of fresh water and disposal of wastewater. Here Supercritical Fluids is one of the contenders.

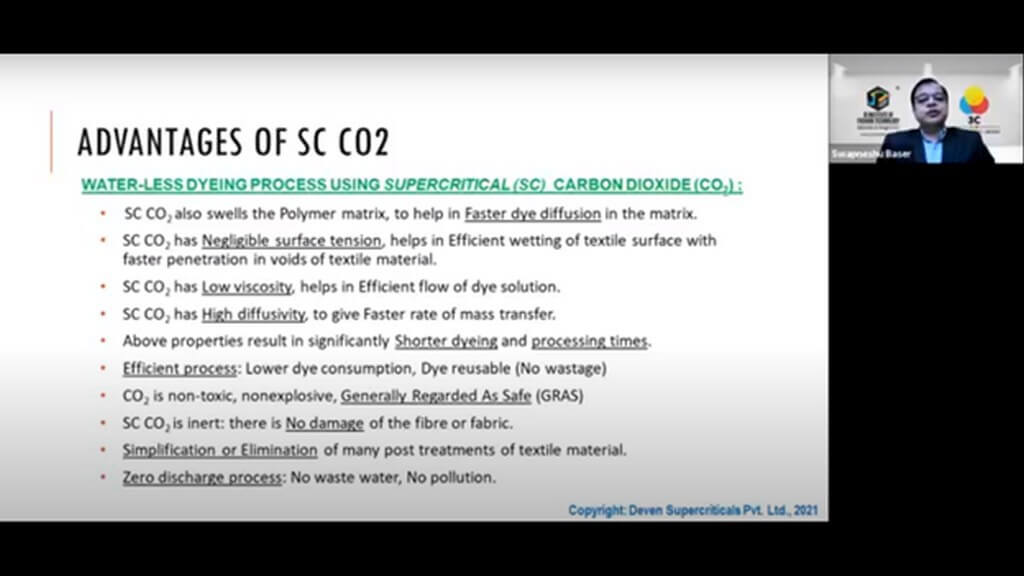

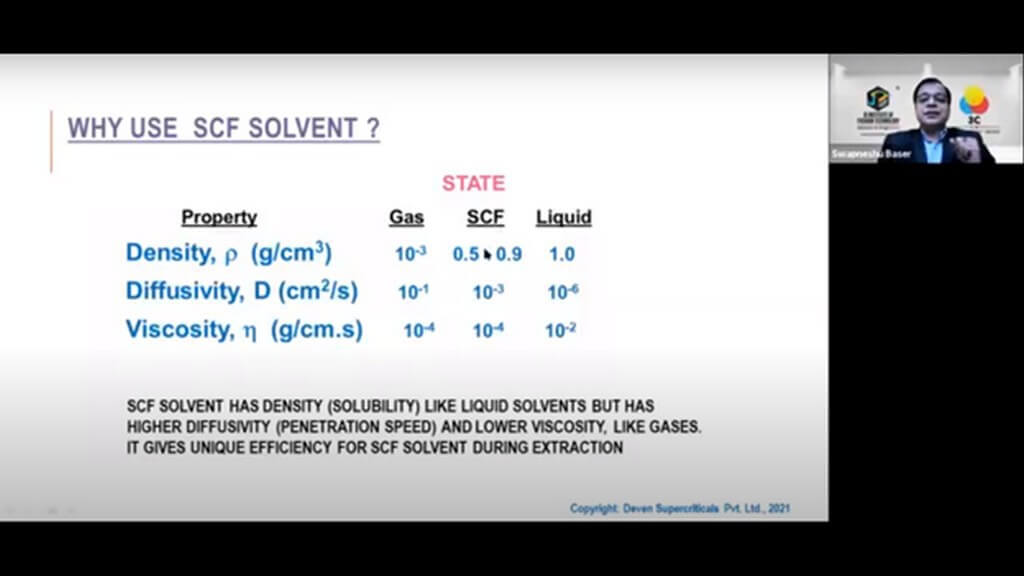

The concept of ‘Waterless’ dyeing leads to the elimination of process-water and chemicals is a breakthrough for the textile dyeing industry. This technology is advantageous as it uses supercritical carbon instead of water. What is the advantage of using SCF? The benefits are aplenty as shown in the image below.

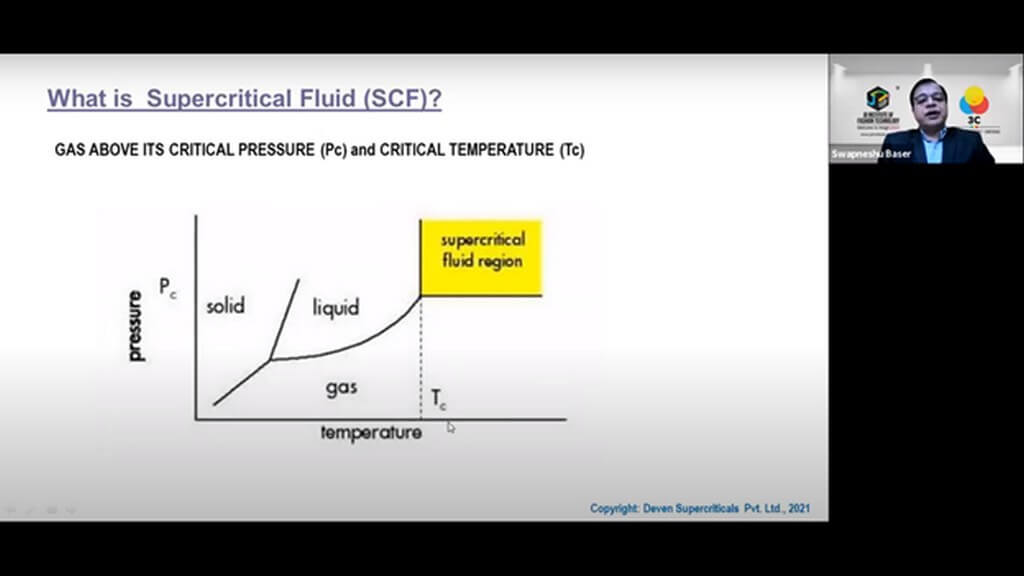

What is Supercritical Fluid?

SCFs have similar solvating influences over liquid organic solvents, but due to their higher diffusivities, lower viscosity and lower surface tension, it makes them further effective. The diagram above clearly shows that co-existence of material after it has been pushed above its critical temperature and critical pressure the molecules of the material cannot come together in the liquid phase. What we get is a high-density gas. This state is known as supercritical fluid. Here we get a fluid that has solubility of liquid but flow property of gas.

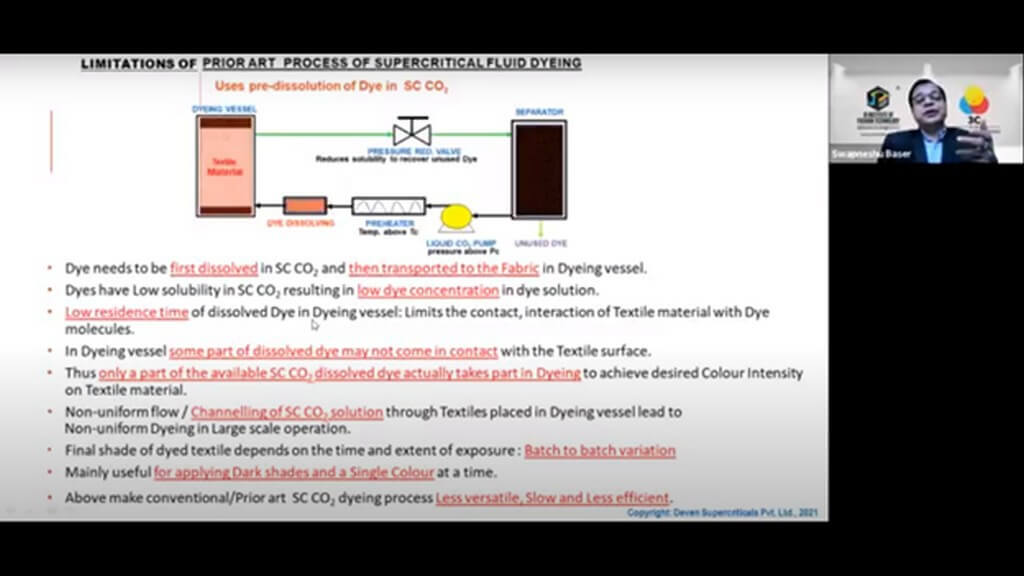

SC-CO2 has been used or its application for dyeing purpose has been talked about, researched and commercialized for quite some time now. Around two decades ago Supercritical Fluids created a buzz in the research community and in the last one decade there are commercial brands that have come up. However, there are some limitations of prior art technology. The dye has very low solubility in the SC-CO2. First when it has to be dissolved in SC-CO2 the concentration will be low in this solution. On top of it the vessel is quite small, so there is low resistance time. The amount of contact time between the dye the SC-CO2 is less, so both the things will have low concentration of dye in the SC-CO2 stage which is going to the textile, dyeing will take time. At the same time, you will observe that when a bundle of material is put in the dyeing vessel there can be a chance that you will have some area where the dye will not come in contact with the textile. There will be a chance there will be a channeling effect wherein the resistance to the flow is low in comparison to the other parts of the fabric and there will be unequal flow across the fabric, which means unevenness of the dye.

Any material which is used by us is not made of a singular colour, there are a number of shades that are mixed to get a single colour. Each colour molecule is different from each other and accordingly it will have a different solubility in SC-CO2. When there is a mixture of three colours the most soluble colour will come out first, then the second and then the third. Hence the shade will not be the one that we desire. These limitations make the process less versatile, slow and less efficient.

Due to these restrictions DSPL came up with their own solution.

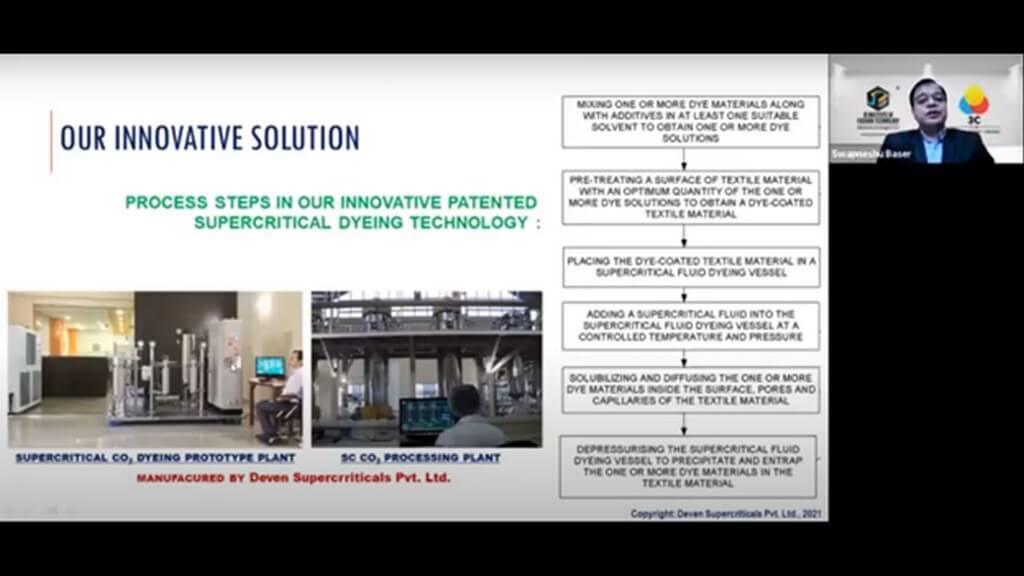

The image on the left is a dyeing SC-CO2 prototype based in the Mumbai plant of DSPL whereas the one on the right is a commercial scale SC-CO2 processing plant manufactured by DSPL, however this is not meant for dyeing purpose, the principles are the same. The solution that DSPL came about was to coat the fabric with the disposed dye. In doing when a thin uniform layer of the dye is applied on the fabric, the surface level of the dye is increased to get a particular shade. This leads to much faster rate of dyeing and creates uniformity in the distribution of the dye on the material.

The advantages of the process implemented by DSPL is simple, versatile and efficient. The process can use traditional dyes which are conventionally used by user industry. Thus, it is not necessary to use special dyes as recommended by prior art process. Dye molecules are not required to be transported as Dye solution in Supercritical medium from Dye Mixing vessel to the Textile surface placed in the Dyeing vessel. It is not critical for the dye solution to be distributed uniformly over each part of roll of the textile material kept in the dyeing vessel for achieving uniform and reproducible dyeing. This enables efficient dyeing with desired uniform, reproducible colour shade on textile material even with light shades along with finishing in a single step. This innovation also allows to scale up dyeing process easier as desired Dye molecules are already available on entire surface of the pre-coated textile material kept in the dyeing vessel.

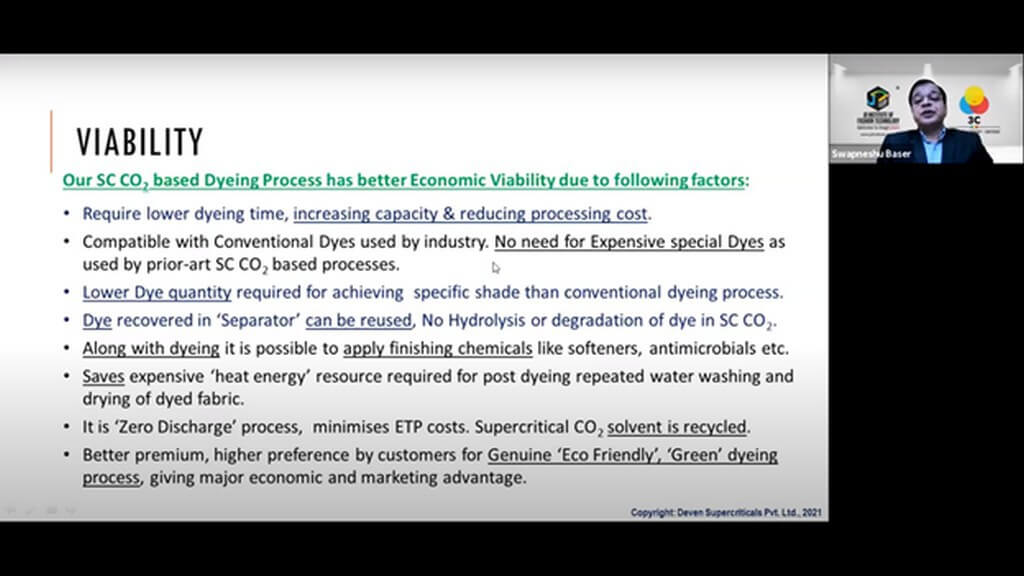

The SC-CO2 based dyeing process by DSPL has economic viability due to the following factors.

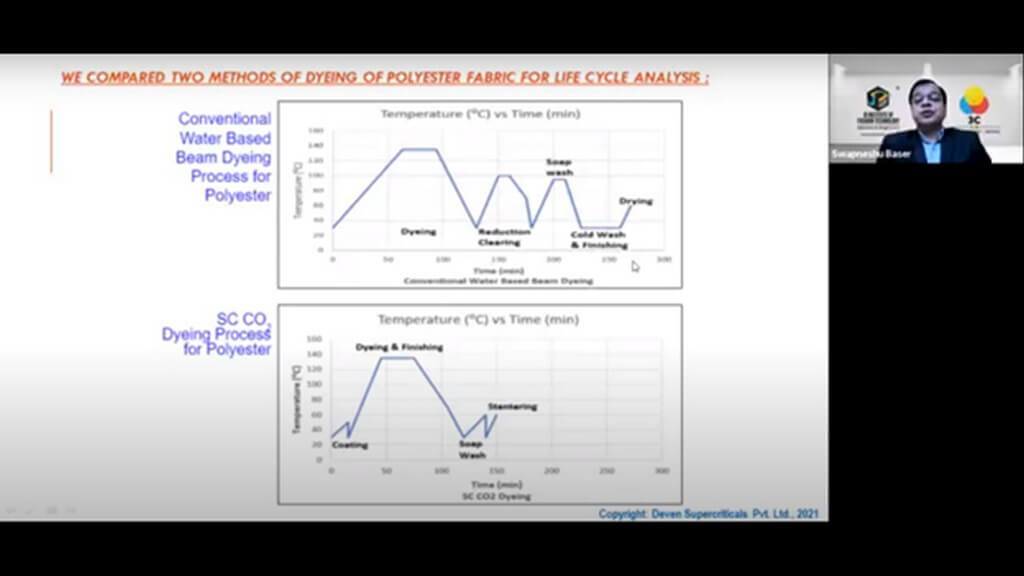

The comparison between DSPL patented dye process and water-based dyeing.

The steps followed for conventional dyeing are more as compared to SC-CO2 dyeing with less time consumption.

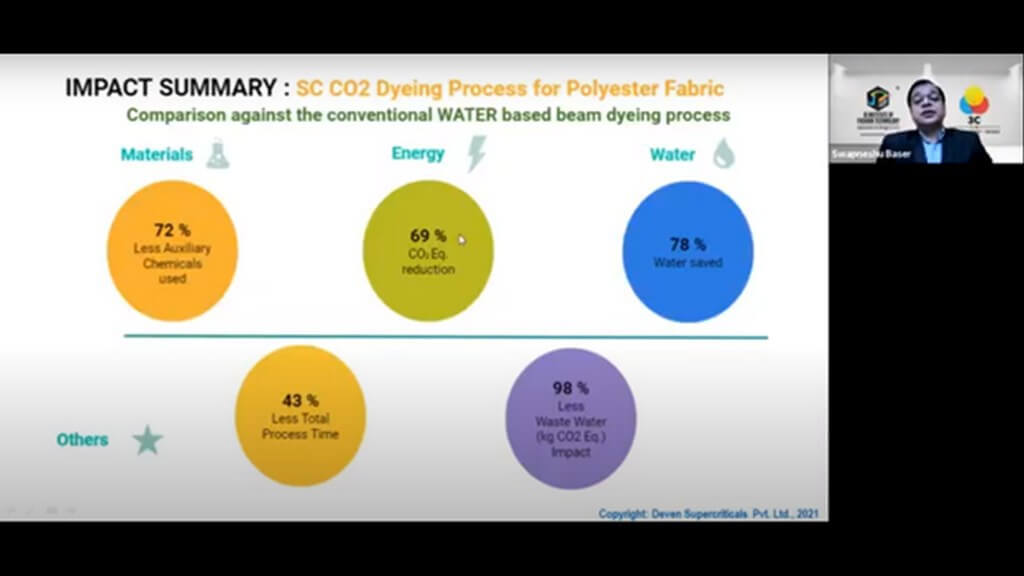

The life cycle of textiles involves a number of stages from agriculture, industry, distribution, use and recycling. The production and consumption of textiles in relation to the environmental impacts has received attention in recent years. Superfluous utilization of fresh water and discharge of wastewater has caused major environmental hazards for the growth of the textile industry besides other issues like solid waste and energy management.

Textile industry has fast-tracked efforts to reduce or eradicate water consumption in the areas of wet processing. Its application in textile processing have many advantages. Positive environmental effects range from drastically reduced water consumption to eliminating hazardous industrial effluent. Furthermore, economic benefits include increased productivity and energy savings.

The long-term viability of the Indian textile industry falls heavily on sustainable water management. Textile industry in general has an enormous water footprint. Conventional water-based dyeing of textile fabrics is detrimental for the environment due to the copious amount of water usage. In addition to water use, the impact of textile wastewater into water resources must also be considered due the discharge of various chemicals into the water bodies This causes negative bearing on the flora and fauna that dwells in the water bodies. The consequences are inadvertently borne by animals and humans who end up consuming this water.

The Innovation in Sustainable Dyeing championed by Dr. Swapneshu Baser and his organisation through the use of Supercritical Fluid technology is a proactive approach or pollution prevention approach that is beneficial to create a sustainable and eco-friendly textile industry. This was especially beneficial for students from BSc. in Fashion and Apparel Design, Advanced Diploma in Fashion Design and Diploma in Fashion Design.